Product

FuelSave works on the principle of BlackBody radiation, the coating improves the Emissivity of the substrate its applied upon. FuelSave in primarily applied over the hot face of refractory surfaces of the High Temperature Furnaces wherein there is no physical contact between the stock & refractory.

FuelSave Technical Information

Emissivity is the ratio of total heat emitted from the surface of any body of material over a specific period of time, over a given surface area at a particular temperature and wave length when compared to that of a “black” body under the same conditions. All materials have an emissivity value which is reported somewhere between 0 (lowest) and 1 (highest), a “black” body has an emissivity value of 1, but this is a hypothetical or imaginary concept, because there are no known materials which can be classified as a perfect “black” body, i.e. have the ability to radiate out 100% of the energy it absorbs. There are however substances which do exhibit extraordinarily high emissivity charateristics (factor close to 1), even at elevated temperature and these are known as "grey" bodies. FuelSave is one such material.

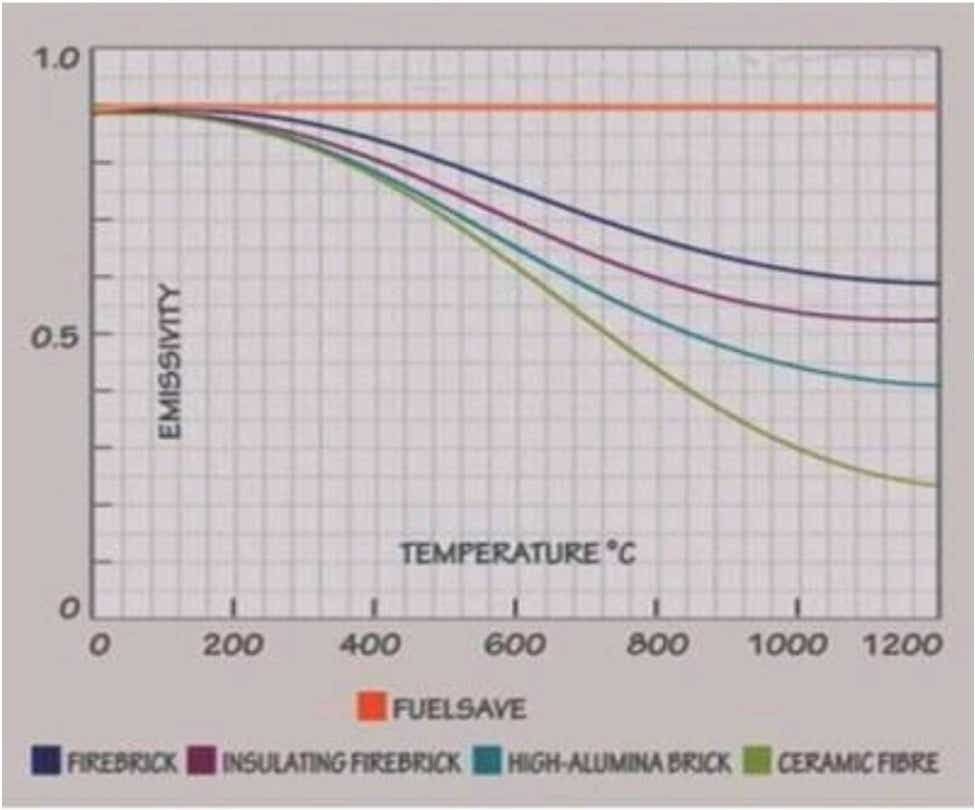

The surface of most materials demonstrate good levels of emissivity at ambient temperature, however this often decreases substantially with an increase in temperature. Refractories are no different and although such materials have been developed to retain most of their physical and chemical properties at very high temperatures, they too lose radiative capacity (emissivity) as temperatures rise. Therefore materials which demonstrate a lower "emissivity factor" will effectively contribute less heat, in the form of radiation, back to the operating atmosphere.

Any refractory substrate, irrespective of type, density or chemical composition which is treated to a coating of Fuelsave will see its surface emissivity characteristics transformed and become similar to those of a grey body. The graph Fig I demonstrates how the emmissivity characteristics of a few common refractory materials change as temperatures rise, it also illustrates how emissivity will improve following a treatment of FuelSave.

For example a dense 50% alumina refractory which may typically exhibit an emissivity factor of 0.6 at 1200C, will, post FuelSave treatment, yield a much higher emissivity factor and demonstrate "grey" body characteristics. Only substances which have grey body properties will demonstrate radiative stability and maintain emissivity at elevated temperatures.

The impact of improved emissivity is explained in the Stephan Boltzman’s law as per which

E = σT 4

In the above-given formula,

E = radiant heat energy emitted from a surface of the unit area in time one second.

σ = Stefan-Boltzmann constant.

T = Absolute temperature.

FUELSAVE coated refractory surfaces help prevent dust and ash deposit adhesion, which preserves the refractory surface and radiation capacity, moreover it protects refractory from the corrosive effects of sulphur and other chemicals contained in various types of fuel.

Features & Benefits of FuelSave

- Is suitable for use in all hot air/gas furnaces using any type fuel.

- Usable temperature range of 750 °C to 1700 °C

- Suitable for all types of Refractory Surfaces New, Old, Dense & Soft

- Improves Efficiency of Furnaces

- Increases Throughput for Furnaces

- Reduces Carbon footprint of Furnaces

- Specific Energy savings range from 5% to 15% depending on nature of operation and refractory substrate.

- Ease of application, rapid turnaround and no re-structuring or physical changes required to process.

- Return on investment generally achieved within a few working weeks.

- Savings on periodic refractory maintenance cost due to inherent chemical resistance and non stick characteristics.

- Improve glazing in ceramic tiles roller kiln.

Go Green With FuelSave

FuelSave not only helps in improving efficiency of Industrial Furnaces but it also contributes towards reducing the carbon emissions of these furnaces which mostly use fossil fuels & thus reduction in specific energy consumption directly helps the green house gas emissions due to these operations. Thus several major industries have taken up FuelSave as a part of their decarburization initiatives.

How FuelSave is Different

A pertinent question which comes to mind is how FuelSave different from is numerous High Emissivity Coatings across the globe, High Emissivity Coatings have been conventionally been ceramic based coatings which have found limited success & though the science totally supported its use but since it was not found to provide desired results the use of these coating in industries almost ceased in modern times but FuelSave is a novel product which has addressed most of the issues faced by these ceramic coatings but in a totally different approach. The chart below explains the difference.

Difference of Fuelsave & Ceramic Coatings

| S.No | Features | Fuelsave | Water based ceramic coatings |

|---|---|---|---|

| 1. | Physical | A single phase (liquid) solvent based solution | A slurry of water based solution of 2 phase (solid/ liquid) of fine refractory particles dispersed in water. |

| 2. | Adhesion | Inherently has excellent adhesive strength & makes a very strong bond with the refractory surface even stable at temperature around 1700C. | Has no adhesive strength of its own but only relies on sintering of powder material with each other as well as refractory surface. |

| 3. | Stability at high temperatures | Excellent stability at high temperatures and will show no blisters or peeling even after years. The coating impregnates in refractory & the film is elastic in nature to compensate for thermal expansion & contraction. No cracks on the film will be observed even after prolonged usage. | Since the co-efficient of expansion of powder material & refractory walls are different the coating peels off and cracks emerge after one of two months of application. |

| 4. | Film Thickness | 20/25 microns on 3 coats | More than 3mm. |

| 5. | Heat retention | It works on the principle of high emissivity which reflects heat from the walls towards the furnace chamber | It has low emissivity but is an insulator which would only increase insulation of brick walls but as cracks & blisters emerge they loose insulation too. |

| 6. | Refractory life | Since the heat stored in the walls is lesser & since the coating does not allow carbon or soot to stick on the walls, the refractory life increases substantially. It is applied on the floor too thus not allowing scale deposits to adhere enabling easy removal of scale. Provides protection from corrosive gases to all walls. All furnace walls will be smooth even after prolonged use. | Is usually applied on ceiling of the furnaces & since spalling takes place inadequate protection to refractory. It cannot be used on hearth of refractory & cannot solve issue of scale deposition. |

| 7. | Non stick Properties | The cured film of Fuelsave will be nonstick in nature and will not allow scale, ash etc to adhere to the refractory surface. This helps in improving refractory life also allows its usage in solid fuel furnaces. | The film comprising of refractory particles does not have any nonstick particle, rather the coarse surface will have increased affinity towards ash etc. Cannot be used in solid fuel furnaces. |